-

About UsShanxi Carbon New Material Technology Co., Ltd. is a service-oriented environmental protection material enterprise focusing on scientific research, development and processing. The company has developed well and its operating income has increased year by year.

-

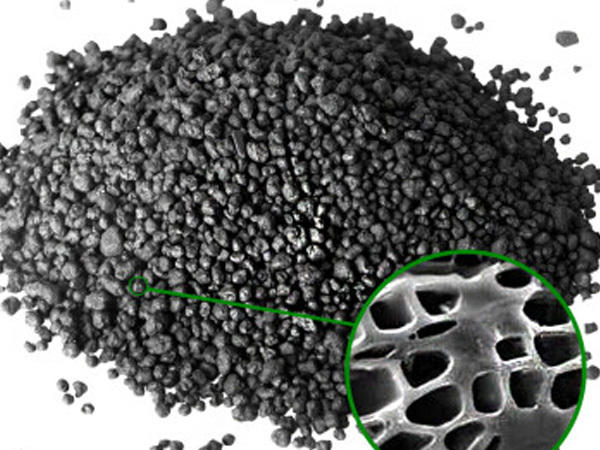

ProductsActivated carbon refers to the carbonaceous material after carbonization, activation treatment, with developed pore structure, large specific surface area, selective adsorption capacity of carbon adsorbent.

-

ApplicationsProducts are mainly involved in sewage treatment, water depth treatment, waste incineration, flue gas desulfurization and denitrification, gas refining, solvent recovery and other industries, to provide more suitable activated carbon products and supporting solutions.

-

NewsTimely understanding of carbon section new material science and technology news trends, the exchange of industry dynamic information.

Products are mainly involved in sewage treatment, water depth treatment, waste incineration, flue gas desulfurization and denitrification, gas refining, solvent recovery and other industries, to provide more suitable activated carbon products and supporting solutions.

VIEW MOREProducts are mainly involved in sewage treatment, water depth treatment, waste incineration, flue gas desulfurization and denitrification, gas refining, solvent recovery and other industries, to provide more suitable activated carbon products and supporting solutions.

VIEW MOREProducts are mainly involved in sewage treatment, water depth treatment, waste incineration, flue gas desulfurization and denitrification, gas refining, solvent recovery and other industries, to provide more suitable activated carbon products and supporting solutions.

VIEW MOREHow to identify the quality of activated carbon

Release time:

2024-05-21

Activated carbon adsorption capacity is another manifestation of the decolorization ability, activated carbon can be colored liquid into a light or colorless magical ability, this is actually because activated carbon adsorption of colored liquid pigment molecules in the cause. Because of this characteristic of activated carbon, it is widely used in the production process of brown sugar to white sugar in the sugar industry. Take two transparent cups, put pure water into one cup, and then drop a drop of red ink (any pigment that is easy to observe but does not change the nature of water can be used here, such as blue ink and printer color ink, but ink and carbon ink cannot be used). After stirring evenly, pour half of the colored water into the other cup for comparison.

Activated carbon adsorption capacity is another manifestation of the decolorization ability, activated carbon can be colored liquid into a light or colorless magical ability, this is actually because activated carbon adsorption of colored liquid pigment molecules in the cause. Because of this characteristic of activated carbon, it is widely used in the production process of brown sugar to white sugar in the sugar industry. Take two transparent cups, put pure water into one cup, and then drop a drop of red ink (any pigment that is easy to observe but does not change the nature of water can be used here, such as blue ink and printer color ink, but ink and carbon ink cannot be used). After stirring evenly, pour half of the colored water into the other cup for comparison.

There are two types of batch operation and continuous operation using activated carbon:

1) Batch operation is often used in the size of powdered activated carbon. The equipment used is: different sizes of barrels, tanks, tanks and other containers, filters, agitators, etc. There are various types of filters, such as ordinary filtration, vacuum filtration or pressure filtration.

2) continuous operation is often used in the use of granular activated carbon large-scale production, equipment and devices are:

a. Fixed bed is a method in which activated carbon is used as a filling layer and fluid flows continuously from above or below for adsorption, because activated carbon in this equipment is fixed during operation. The fixed bed has single bed, multi-bed series and multi-bed parallel connection according to the fluid volume and processing requirements.

B, moving bed, refers to the activated carbon intermittent mobile adsorption. The fluid to be treated flows in from the bottom of the adsorption column and is in countercurrent contact with the activated carbon, and the treated fluid flows out from the top of the column.

C, flow bed, this is a continuous flow bed adsorption method, the early decolorization of sugar. The activated carbon forms an expanded layer or a fluidized state in the tower, contacts more with the fluid entering from the bottom of the tower, and then continuously discharges out of the tower. If the fluid flow rate is too large, the expansion rate of activated carbon in the tower increases, and the layered movement cannot be maintained, so the flow rate must be strictly adjusted.

Key words:

Activated carbon

Carbon

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

RELATED INFORMATION

Address: 24th Floor, Building B, No. 8 Zhichuangcheng, Wanbailin District, Taiyuan City, Shanxi Province, China

Telephone: 86 351 4250555

Mobile: 86 13754813618

E-mail:wwh@shanxicarbontech.com

QR code