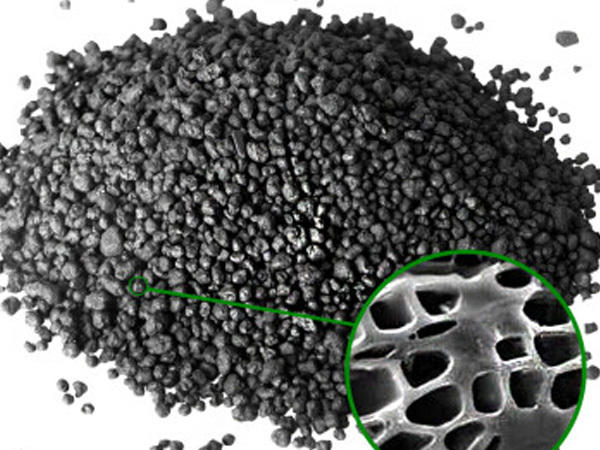

Raw material selection of coconut shell activated carbon

Release time:

2024-05-21

Coconut shell activated carbon It is a waste renewable energy fuel, the calorific value is higher than similar raw materials of coconut shell activated carbon, which is currently recognized as the most ideal mechanism of coconut shell activated carbon raw materials. Due to the moderate lignin content of larch and fiber knot compact, good density, so that it can be formed at a lower molding temperature and less extrusion pressure density high hardness good molding rod. Coupled with a good firing technique, it can eventually be made into a mechanism of excellent quality carbon. Almost all pine wood is suitable for making machine-made charcoal. However, due to the difference in the nature of the ingredients, we will also encounter different problems in production.

Coconut shell activated carbon It is a waste renewable energy fuel, the calorific value is higher than similar raw materials of coconut shell activated carbon, which is currently recognized as the most ideal mechanism of coconut shell activated carbon raw materials. Due to the moderate lignin content of larch and fiber knot compact, good density, so that it can be formed at a lower molding temperature and less extrusion pressure density high hardness good molding rod. Coupled with a good firing technique, it can eventually be made into a mechanism of excellent quality carbon. Almost all pine wood is suitable for making machine-made charcoal. However, due to the difference in the nature of the ingredients, we will also encounter different problems in production.

For example, some pine fibers are not ideal, making it difficult to form. For example, once the fiber knot of white pine is destroyed, it is difficult to recover, and it is difficult to get a good mechanism rod even under high molding temperature and extrusion pressure. This requires us to mix other raw materials to improve its bonding ability. If we overcome the weakness of white pine in molding, we can also use it to burn out the high quality mechanism of carbon.

In addition, the density of some pine trees is not very ideal. For example, camphor pine, which grows in Manzhouli area of Heilongjiang Province and in Russia, belongs to pine trees and has a long growth cycle, but the wood is still soft, which makes us often feed insufficient when processing this raw material, resulting in cracks in the forming rod. In view of this situation, we can properly adjust the propeller pitch or increase the screw diameter to overcome. Due to the different growth regions and growth cycles, the composition ratio and structural characteristics of various pine trees are different, but if we can make a reasonable and accurate analysis of these and take appropriate measures, pine wood is still a very ideal raw material.

Coconut shell activated carbon raw materials are hardwood. There are a wide variety of hardwoods, such as birch, basswood, elm, green dried willow, and most fruit trees and various southern bamboos can be classified into this file. Its growth years are generally between pine and softwood, and the wood is harder. Most of them can be used as raw materials for machine-made carbon. However, due to the obvious differences in its composition characteristics, it is often difficult to produce as a raw material. One of the obvious problems is the weak viscosity and ability, for some of the raw materials simply mixed with other wood raw materials can not solve the problem. The use of hardwood for production, the technical requirements are very high.

Key words:

Activated carbon

Carbon

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

RELATED INFORMATION